Covid-19 Closure What Should I Do With My Draught System?

Steve Riley BetterBeer.com

We are fielding many calls about what to do with your draught system while your establishment is either closed or selling take-out and delivery only. With no draught sales, what should you do?

You have two options:

Do you want to be ready to start pouring beer once service resumes but are willing to pay for the hydro and ongoing cleaning costs? Then choose Option A.

If you want to save hydro and potential ongoing cleaning costs but accept that you must clean before service which means you are not pouring draught right away once you open for regular business, choose option B.

Each option has different information depending on your system set up:

All of these options assume that you are not using an air compressor to push your beer.

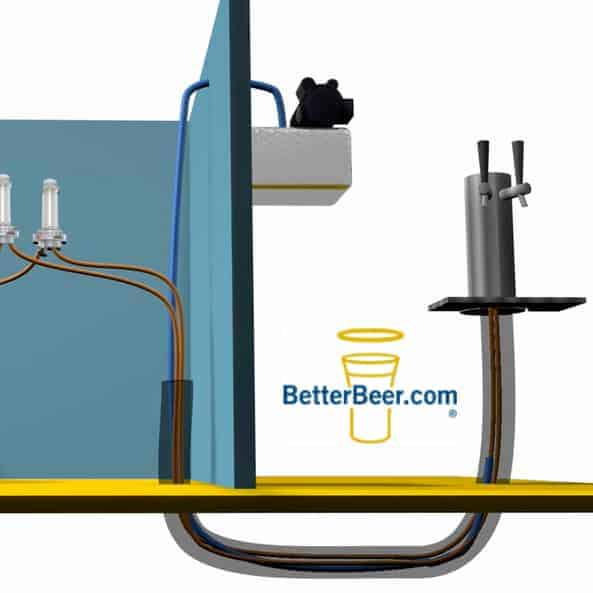

Long draw:

A long draw system has kegs in a walk-in cooler and the beer runs to the bar through a trunk line. 98% of establishments who sell draught have a long draw system. Here are the two options for Long Draw:

Option A

If you are still open but your bar and restaurant are closed (selling takeout and delivery only) then this is probably your best bet.

Leave your system running.

- Keep your glycol deck/line chiller on, your beer will not freeze in the lines. However, see Sub Zero / Extra Cold section below.

- Keep your beer gas system or gas cylinders on.

- Beer walk-in fridge stays on

If you are still selling take-out and delivery, you have some staff and suppliers coming through your doors. Your draught service tech should be one of them as well. Have them come in and clean your lines on your regular frequency. If you use our electronic line cleaning tracking – scan the code and record your cleans as usual.

Pros: Why this works – you are using beer gas and your system will stay cold and clean. Beer in the lines is as good as beer in the keg when it is cold and using beer gas (no air). When you do open up the doors for business, it is business as usual. Start selling draught immediately. Beer is the best thing to have in your lines, it is better than water, line cleaner, or CO2, because you can never eliminate the residual water/moisture. Beer takes better care of itself.

Cons: Why you may not want to choose this option – you are paying to keep the system cold which consumes hydro and you are paying for line cleaning every cycle. If the closure lasts a while, this could add up to a significant cost.

Option B

When golf courses close at the end of the season and don’t sell draught until the following spring, their systems are shut down. Option B is to shut the system down completely.

Shutting the system down requires the following:

- Lines are cleaned and instead of re-packing with beer, they are blown dry. You can never get them completely dry, but they are empty of beer, water, and cleaner.

- The gas and glycol decks/line chillers are turned off

- The walk-in is left on to keep your kegs cold. Warm keg’s shelf life deteriorates quickly, meaning brewery-recommended shelf life is based on kegs staying cold. All full and partial kegs must be in the walk-in to stay cold.

Pros: Why this may work for you – It saves hydro and limits any issues as the system is off. The risk of any line or gas leaks or freezing is negated.

Cons: Why this may not work for you – you must get your lines cleaned again before serving resumes. Again, it is impossible to get all moisture out of the lines and you will have growth in the lines. They must be cleaned before service. If a tech has 200 accounts and they clean 5 a day, that is 40 business days until everyone is up and running. This may put you at a competitive disadvantage.

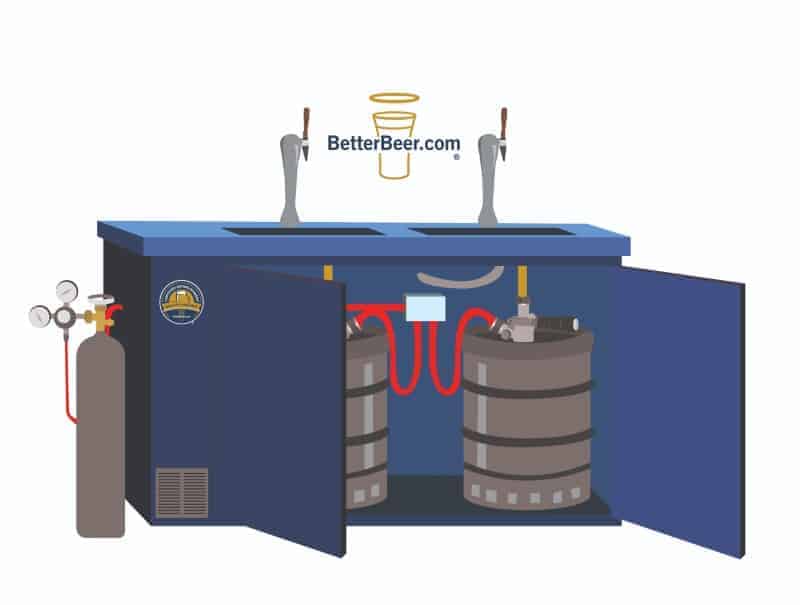

Direct Draw

Where the kegs are located directly below the taps in a self-contained cooler box (kegerator).

Option A

Leave it running as you do in option A above. Pros – ready to go upon re-opening. Cons – ongoing hydro and cleaning costs.

Option B

Shut it down, move the kegs to the walk-in. Pros – saves hydro and ongoing cleanings. Cons – must have line cleaners clean your lines before re-opening and selling beer.

Molson Sub Zero System

This is a tough one, I am not going to lie. The Sub Zero system is designed to keep the beer really cold. Because it rides the fine line of cold and freezing, there is a chance that the beer in the heat exchange or the tower will freeze.

Option A

Leaving the system up and running – I would recommend pouring a pint or two every day to lower the risk of freezing. If it does freeze you can unplug the Sub Zero deck to let it thaw and then plug in again after 30 minutes. An additional con to this option is that you are paying hydro to keep the towers frozen for no reason.

Option B

Shutting it down – same as above, you’ll need to clean the system before service resumes and you sell beer again.

Heineken Extra Cold

These towers have a thermostat designed to shut off the tower freezing during non-service times (usually 1am – 10am). This will eliminate the chance of the beer completely freezing in the lines.

The options are the same A or B but think of Heineken Extra Cold the same as you would any other brand. Pros and Cons are the same as above except if you choose to keep it on (Option A) you are incurring extra hydro costs as the towers are being chilled constantly through service times despite no beer going through them.

Ask your draught service provider to adjust the downtime timer to removing freeze risk as well as extra hydro use.